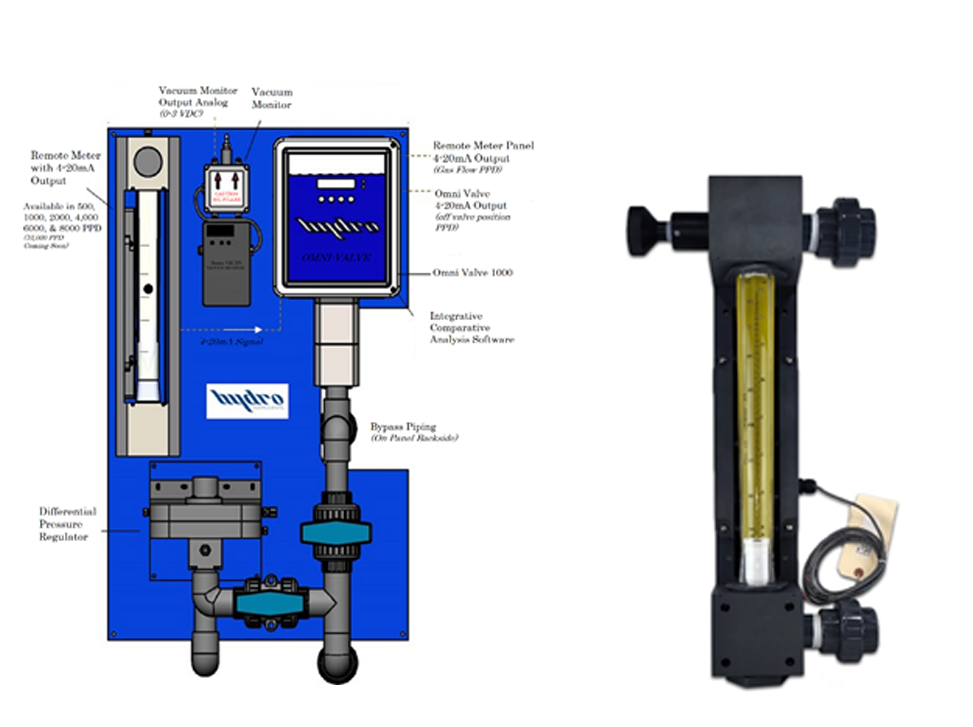

Global Treat, Inc., established in 1994, is a supplier of industrial grade Water and Wastewater Treatment technologies for Municipal, Petrochemical and Oil and Gas Production applications. With the support of our exceptional staff, manufacturers, network of regional distributors, and representatives, Global Treat, Inc. provides professional customer service, technical assistance, and installation experience. Our success is derived from our new and long term customers who provide us with necessary and sought-after feedback for a wider variety of offerings and continual product improvements.