CASE STUDY: Wastewater Aeration Global Treat Inc. Provided a Texas Wastewater Treatment Plant with an Air Induction System that resulted in a Cost-effective Solution to Maintaining the Required Level of... read more →

February 7-8, 2017 New Orleans, LA Cooling Tower Institute 2017 www.coolingtechnology.org February 16-18, 2017 San Marcos, TX Texas Wine & Grape Growers Conference (TWGGA) April 10-13, 2017 Texas Water 2017... read more →

In high capacity chemical feed applications, when does it make sense to use a vaporizer as opposed to the typical direct gas withdrawal system? A vaporizer should be considered if... read more →

An "Eddy", in fluid dynamics, is defined as situation where a current of water is moving in a direction that is different from that of the main current. Global Treat,... read more →

SIMPLE ANSWER: It is effective, simple and contains no moving parts. Problems with Sulfuric Acid in Cooling Towers Sulfuric acid is often added to cooling tower water basins to maintain... read more →

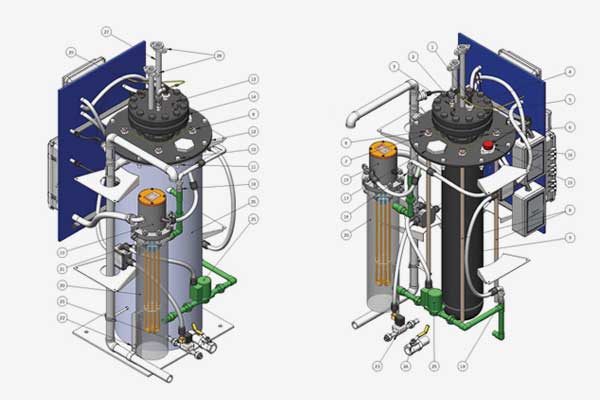

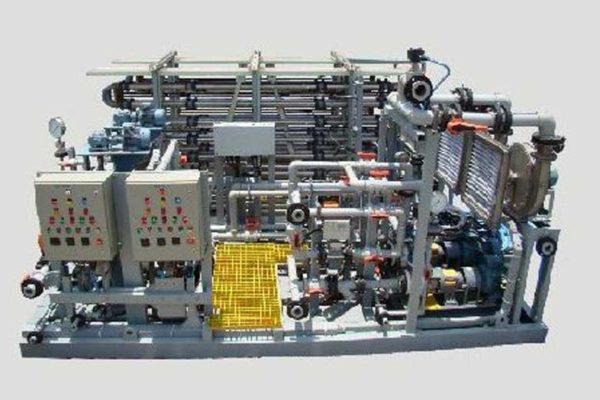

Answer: Electrochlorination, which is the process of producing a non-hazardous chlorine equivalent. This is a process of electrolysis of brine/seawater solution which forms a sodium hypochlorite solution. With this solution,... read more →

Yes! And this is the reason for the development of DioxiGen Systems! The genesis of DioxiGen Systems resulted from a client lunch meeting with the East Rio Hondo Water Service... read more →

Let's begin by explaining how an Automatic Switchover System works. An Automatic Switchover System allows for a Chlorine Gas Feed Systems to automatically switch from an empty chlorine gas cylinder... read more →

Do you have a need to chemically chlorinate or dechlorinate discharged water or wastewater? Global Treat has a full line of Gravity Flow Tablet Feeders that allows gravity to feed... read more →

Answer: Lockable fiberglass shelters provide the peace of mind for storing chemicals and chemical feed equipment and are a cost effective way to protect your equipment in fully customizable shelters... read more →